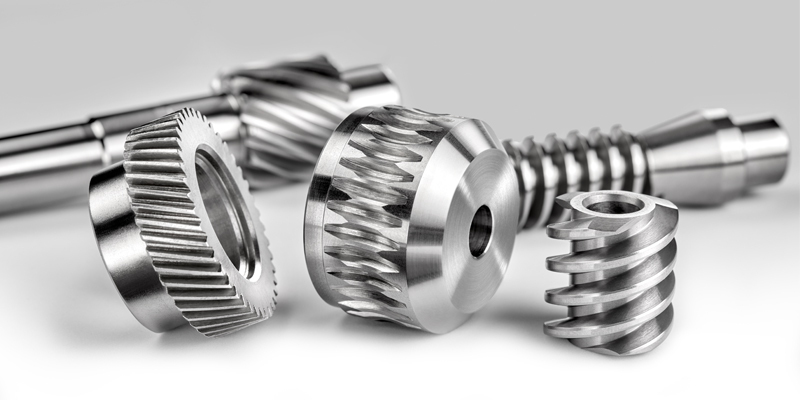

Gear Hobbing

A key process in gear manufacturing is something called gear hobbing. In this process, the repetitive motions of a hob cutting tool and a workpiece, continuously rotating in a synchronized motion, create the gear tooth. Precision hobbing services are essential for manufacturing reliable gears that organizations can count on.

Time-tested techniques and state-of-the-art equipment are central to our custom gear hobbing services. They ensure that we are able to consistently make gears with unparalleled precision. Our commitment to excellence provides enhanced durability and accuracy, ensuring reliable solutions for a wide range of industries that require superior gear performance.

Gear Hobbing Equipment We Use:

Five (5) EMAG/Koepfer 200 CNC Hobbing machines w/autoload

One (1) EMAG/Koepfer 200 CNC High Helix Hobbing/Worm Milling machine w/autoload

One(1) MZ130 CNC Hobbing/Worm Milling machine w/autoload

One (1) EMAG/Koepfer 160 CNC Hobbing machine w/autoload

One (1) Mitsubishi GE20 CNC Hobbing machine

1-Koepfer Model 160 CNC 7-Axis Automated Loading w/skiving (2021)

2-Koepfer Model 200 CNC 7-Axis Automated Loading w/skiving and Servo Distributor (2015, 2017)

1-Koepfer Model 200 CNC 7-Axis Automated Loading with Worm Milling High Helix Hob Head and Skiving (2013)

2-Koepfer Model 200 CNC 7–Axis Automated Loading w/skiving (2008, 2011)

1-Koepfer MZ130 CNC Automated Loading Gear Hobbing/ Worm Milling (2008)

1-Koepfer Model 200 CNC 7-Axis Automated Loading (2006)

1-Mitsubishi GE20 CNC (2010)

2-Mikron 21/1

2-Pfauter RS00

Request a Quote

Please tell us about your needs. We will review your information and get in touch with you soon.

For more urgent needs, please call us at 414-481-5488.