When Quality Matters

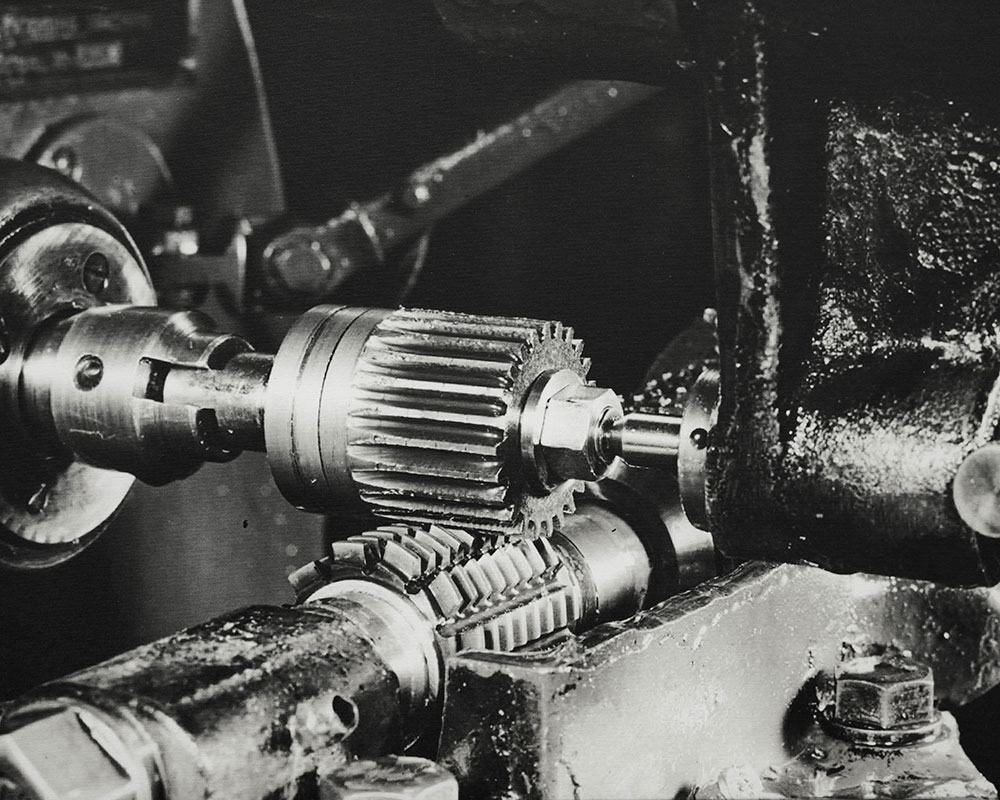

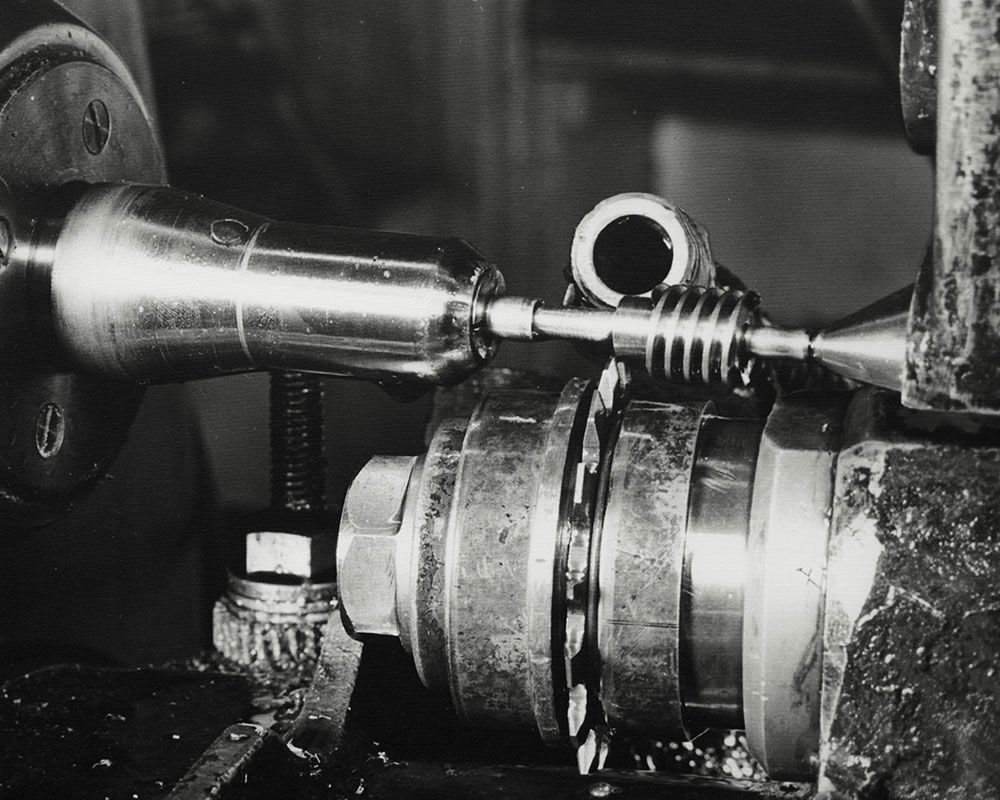

Old World Craftsmanship,

State of the Art Technology

Producing Gears Since 1930

We are a full-service gear manufacturer, offering a wide variety of additional services, including deburring & finishing, grinding, heat treating, honing, prototyping. broaching, CNC machining and gear modifications.

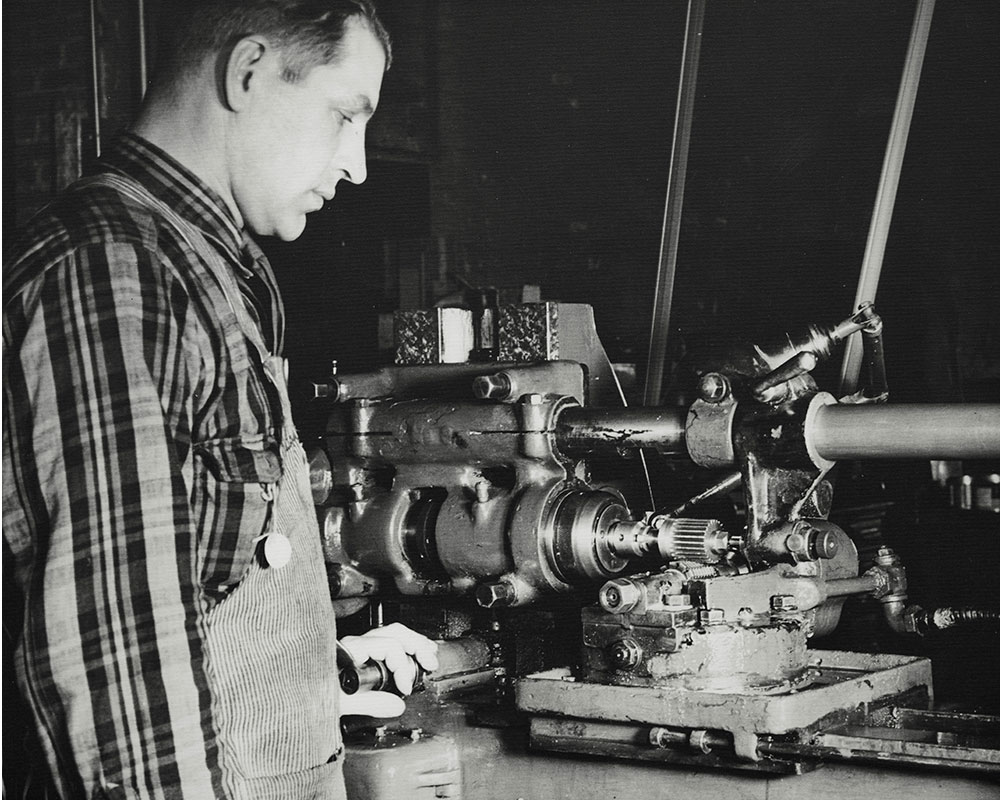

Although manufacturing technology has changed over the years, our dedication to producing quality gears, delivering them when needed, and at a competitive price, continues to make us successful today.

Our ongoing investments in technology, training, and quality assurance measures ensure we meet the demanding requirements of our customers.

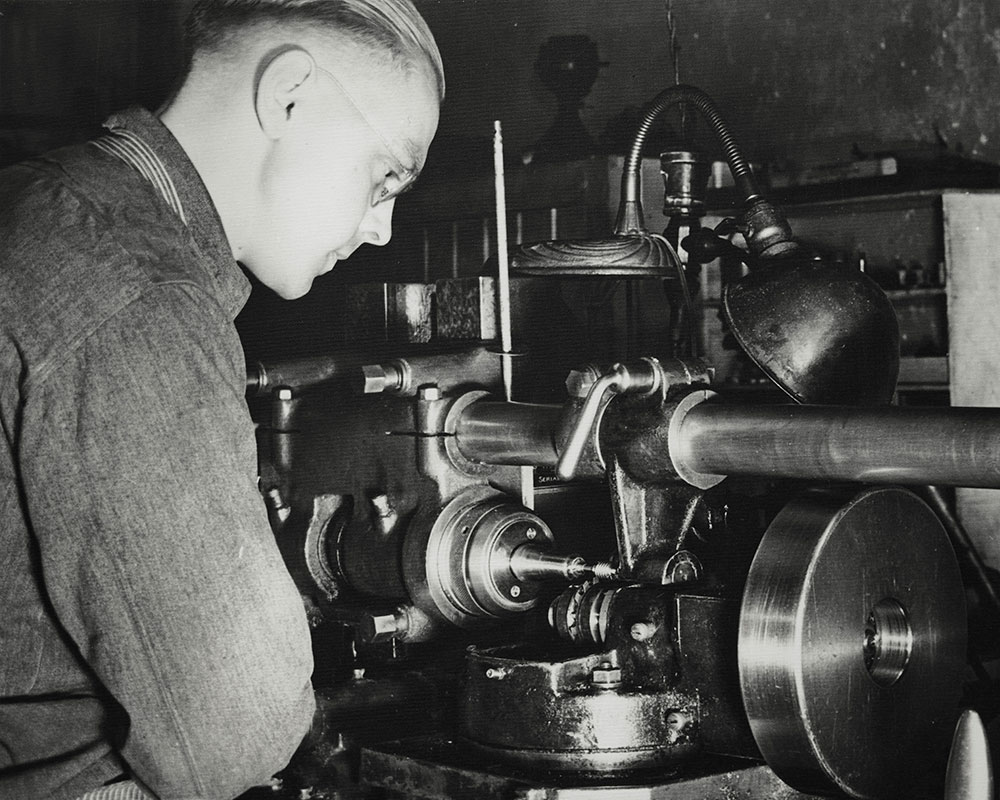

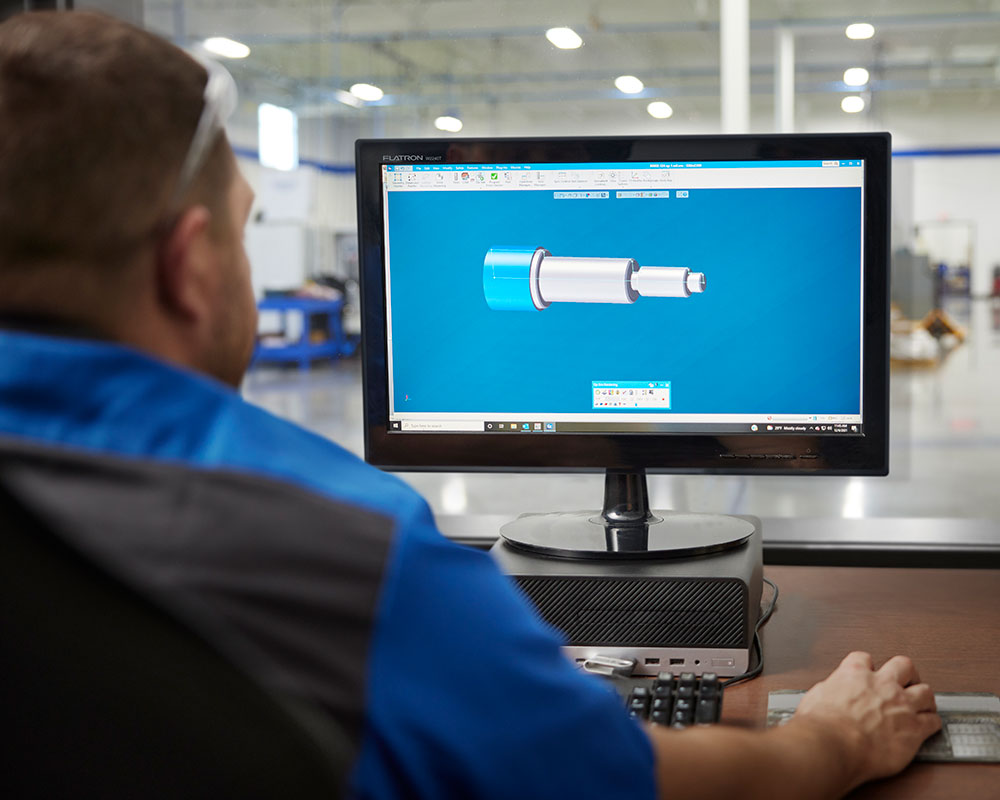

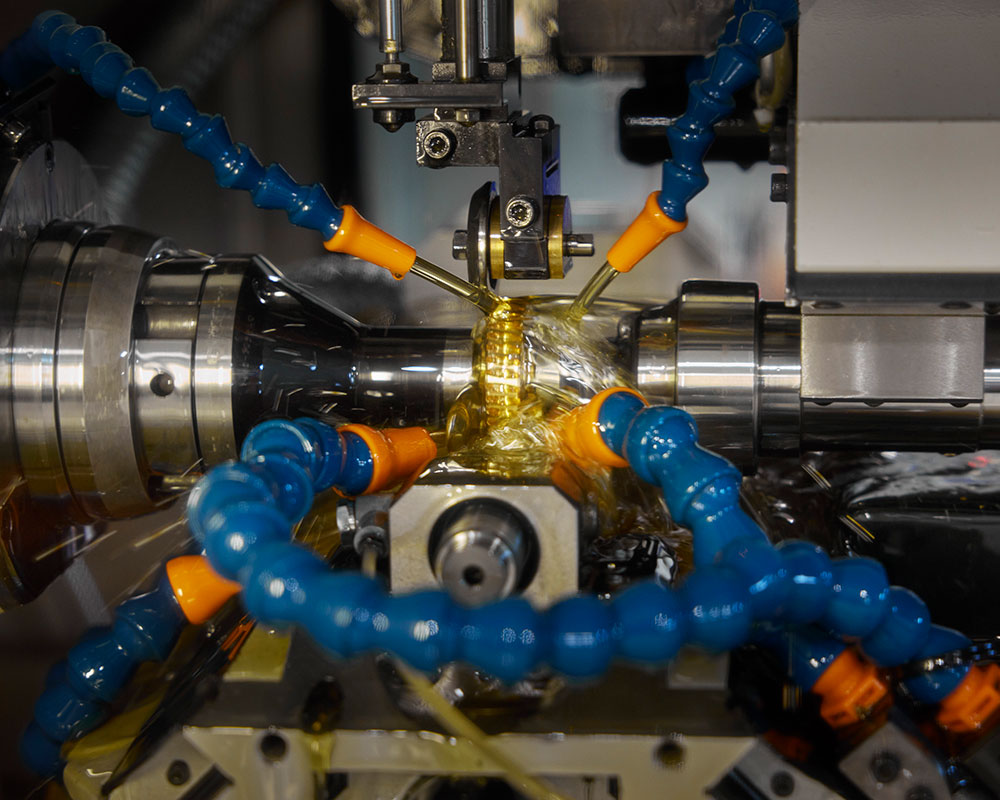

Technology & Training

We understand the importance of precision gear hobbing. That’s why we invest in advanced manufacturing and inspection technology. Our dedicated team receives ongoing training so they can optimize our equipment and provide you with the highest quality products, ensuring your parts are accurate and always meet your specifications. View our Gear Hobbing and Inspection Equipment.

More Than Gears

We enjoy working closely with our customers to understand their full needs, including those that go beyond gears. Our dedication to quality and timeliness extends to:

Deburring & Finishing | Grinding | Heat Treating | Honing Prototyping | Broaching | CNC Machining and Gear Modifications

Always Investing

Our investments in CNC machining technology and robotics make it possible to create precision parts for all of your needs. Whether you’re working on an innovative project design or looking for a new source for existing product, our team is ready to work with you!

Capabilities

At Brelie Gear we put care into every job we take on. Large or small, we are specialized and focused – ready to answer complex and simple requests.

Our growth-oriented approach to business has given us the competitive advantage of investing in in-house capabilities. Quick turnarounds are as important to us as they are to you.

|

Gear Type

|

Size Range | Pitch | AGMA Class |

|---|---|---|---|

|

Spur

|

.250″ to 7.87″

|

5 to 200

|

12

|

|

Helical

|

.250″ to 7.87″

|

5 to 200

|

12

|

|

Worms

|

.250″ to 2.50″

|

8 to 180

|

– |

|

Worm Gears

|

.250″ to 7.87″

|

5 to 200

|

12

|

Crown Hobbing

|

Additional Capabilities

|

|||

|---|---|---|---|

|

Carbide Re-hobbing

|

Turning up to 14″ Diameter

|

Finish machining

|

Broaching

|

Equipment

We pride ourselves in our ability to continually reinvest up to 30% of sales back into our company to stay ahead of the curve with our equipment. Our machines feature the latest automation technology to deliver premium parts made precisely and efficiently, and delivered on time, every time.

Additional Equipment

- 1- Amada Automatic Horizontal Band Saw (2020)

- 1-Koepfer CNC Hob Sharpener (2017)

- 3-Hardinge 2nd Operation Lathes

- 2-Bridgeport Vertical Milling Machines

- 2-Sunnen Precision Honing Machines

Request a Quote

Please tell us about your needs. We will review your information and get in touch with you soon.

For more urgent needs, please call us at 414-481-5488.

Start the Conversation

Are you ready to talk, or want to schedule a visit to our facility? Give us a call.

Contact

Steve Janke

414-481-5488

sales@breliegear.com

Brelie Gear

2350 Corporate Dr.

Waukesha, WI 53189

Ph: 414-481-5488

Fax: 414-481-5866